Aluminium is a product made of aluminium and other alloy elements, usually processed into castings, forgings, foils, plates, strips, tubes, rods, profiles, etc., and then made by cold bending, sawing, drilling, assembling, colouring, etc. Aluminium profiles are widely used in construction, industrial manufacturing, automobile manufacturing, furniture manufacturing, medical equipment manufacturing and other fields.

There are many types of aluminium alloy profiles, the more commonly used in industry are pure aluminium alloy, aluminium-copper alloy, aluminium-magnesium alloy, aluminium-zinc-magnesium alloy, etc. The specifications and models of different types of aluminium alloy profiles are different, so let’s learn about them together!

What is the material of aluminium profile?

Aluminum profile is an application of aluminum alloy product form, that is, aluminum bar (or aluminum plate) through hot melt, extrusion, coloring and other processes to manufacture products.

What are the characteristics of industrial aluminium profiles?

Aluminium profiles have better corrosion resistance, processability, formability and recyclability, and their electrical and thermal conductivity is better than that of copper, and they are non-ferromagnetic, making them more suitable for use in the electrical and electronic industry. However, aluminium alloys are more prone to casting defects such as shrinkage, trachoma, porosity and slagging in the production process.

What are industrial aluminium profiles used in?

Construction: aluminium profiles for broken bridge aluminium doors and windows, curtain walls, etc;

Heat sink: aluminium profile heat sink, which can be used for heat dissipation of all kinds of electric and electronic equipment;

Industrial manufacturing;

Manufacture of automotive parts;

Furniture manufacturing;

Solar photovoltaic profiles;

Rail track structures;

Framing;

Medical equipment, etc.

Classification of industrial aluminium profiles

Classified according to the processing methods can be divided into

Rolled products: sheet, plate, coil, strip.

Extruded profiles: tubes, solid bars, profiles.

Cast products: castings.

Aluminium profiles series

Aluminium profiles are available in 1000 to 9000 series, of which the 6000 series is a common series for construction.

The 6000 series is dominated by magnesium and silicon. Medium strength, good corrosion resistance, good welding performance, good process performance and good oxidation colouring performance. 6 series aluminium alloys are currently one of the most widely used alloy materials.

How to check the quality of aluminium?

Look at the oxidation level: you can scratch the surface of the profile to see if the oxide film on the surface can be wiped off.

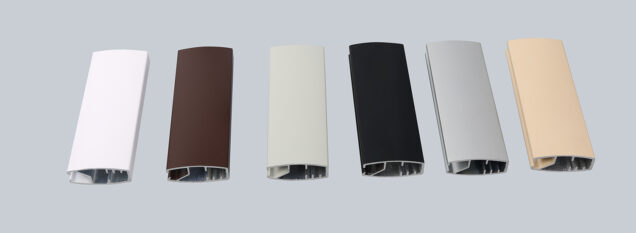

Look at the colour: the colour of the same aluminium profile should be consistent, if the colour difference is obvious, obvious not good.

Look at the flatness: check the surface of the aluminium alloy profile, there should be no depression or bulge.

Look at the strength: you can bend the profile moderately by hand, if the profile is bent without effort, it is not strong enough.